What are the most common problems with cheap laser engraving machines?

Are cheap laser engravers worth the money?

What’s the difference between a cheap laser engraver and an expensive one?

Should I buy a cheap laser engraving machine?

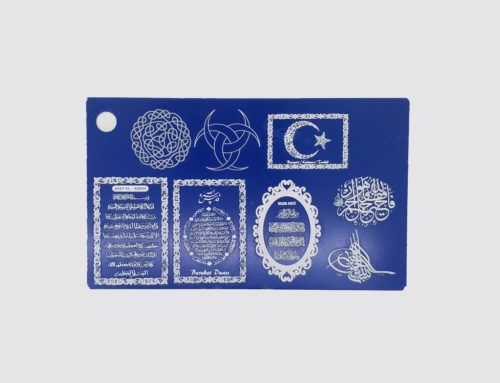

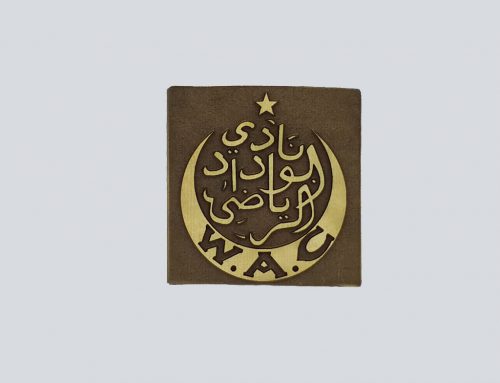

Laser engraving is one of the most exciting technologies available for craftspeople, DIY enthusiasts, and entrepreneurs. A laser engraving machine allows you to transfer your art, lettering or designs onto a versatile range of materials, and there are limitless possibilities for what you can create.

Still, if you’re itching to get out your wallet and fork over your hard-earned cash for the cheapest model so you can get started on a passion project you’ve come up with, it’s important to exercise some caution. Not all laser engraving machines are created equal, and with even the cheapest models costing several hundred dollars, it’s important to invest wisely in a high-quality machine that will last.

This article looks into the most common problems with cheap laser engraving machines, how they’re different from professional or industrial quality units, and whether they’re worth the hundreds of dollars that you’ll fork over for one. We’ll also explain some of the most commonly reported problems with cheap laser engravers, including how they’ll affect the end results you get from your hard work.

Expensive Vs Cheap Laser Engravers – What’s The Difference?

At the high end, laser engravers are compatible with many different types of software and design files, contain durable parts that won’t easily break down, use powerful lasers that can cut through diverse materials, and perform at a precise and fast speed. These high end laser engraving systems also come with comprehensive service packages and warranties that protect you from expensive repairs in case of a malfunction, and include many convenient and useful features that make them easier to operate.

At the low end, laser engravers are often imported from foreign factories where low-skill workers cobble together a working engraver from cheap plastic materials. Key components are often 3D printed from low-cost plastics, and a weaker laser is used to save on costs. The manufacturer won’t provide a warranty on the item, and you’ll be lucky if you can get a hold of them to supply replacement parts for the item in case of a breakdown or malfunction.

Cheap laser engravers also frequently use cheaper, alternative versions of the most popular design software, meaning that you’ll need to jump through hoops to get your designs working at all.

With those items listed as general differences, we’ve asked around for some of the most common complaints associated with cheap laser engravers and included them below.

What Are The Most Common Issues With Cheap Laser Engraving Machines?

Any item that sells with a big price range usually has a corresponding quality range associated with it, and when you purchase a cheap laser engraver for a few hundred dollars, you have to expect that it won’t be long before things start to break down. Here are some of the most common complaints we’ve heard about cheap laser engraving machines:

Laser Doesn’t Cut Some Materials – Smaller and cheaper laser engraving machines use smaller and cheaper lasers, and it’s obvious that a less powerful laser is less effective at engraving. Still, many cheap laser engravers don’t live up to the standards they advertise. Just because a company says that their laser can cut through materials that are 1/2-inch thick, doesn’t mean it can cut through any material with this thickness. Materials like acrylic and soft lumber may work great, but plywood and MDF which contain glue could prove a challenge for a weak laser.

Laser Not Powerful Enough – Cheap laser cutters frequently advertise the wattage of the laser they use, with figures ranging from 100W down to 50W or even less. Sneaky companies may advertise “1500mW” instead of “1.5W”, using the larger figure to make it seem like the laser is more powerful. If you’re primarily using paper as a material, a 1.5W laser might work, but it won’t work for much else. We’ve also heard stories of 50W lasers that really only output 32W of power – you’d be lucky to slice a loaf of bread with that.

Laser Produces Excessive Scorching – Laser engraving is essentially burning the surface of the material. It produces a lot of heat and debris, which can leave the surface of your materials with undesirable and unsightly scorch marks. By focusing a stream of compressed air where the laser meets the material, quality engraving machines achieve smoother cuts, fewer smoke deposits and less scorching, but this feature is almost never present in cheap engraving machines. As a result, it’s difficult to get quality engraving done on wood, acrylic, or paper with a cheap machine.

Software Incompatible with Life – Every artist, whether they be a painter, sculptor, or graphic designer, is naturally limited by their medium. If you’re producing incredible designs in CAD or Adobe Illustrator, you may be surprised to find that your cheap new laser engraving systems comes with its own much simpler design software. That leaves you with two options: either you can learn to use a simpler and less feature-rich version of the design software you know and love, or you can try to import your existing designs into this application you’ve never heard of, in hopes that the engraving machine software can figure out what to do with it. Either way, you’re jumping through hoops and potentially losing the opportunity to produce your best work.

Laser Engraver Breaks Constantly – If you’re spending under $1000 on a laser engraving machine, you need to understand that in addition to the important features that are missing, many of the important components will be cheaply sourced, poorly made and prone to damage. Unless you’re a skilled technician, you’ll find it near impossible to figure out what broke, whether you can fix it, and what steps are required. Be prepared to open your wallet again for repairs, or to park the machine in the attic with the rest of your junk.