Over the past decade, laser engraving machines have revolutionized the jewelry industry. We see a constant increase in jewelry businesses that utilizing laser technology to offer bespoke and customized items for their customers. This article explores the benefits of laser technology and shows you some of the main advantages compared to traditional engraving methods.

Multipurpose

Foremost, a single laser system can engrave multiple surfaces. That means that you only need to buy one laser engraving machine to be able to engrave silver, gold, copper, titanium, brass and tons more applications. In fact, a fiber laser machine can also engrave non-metal surfaces, such as acrylic, plastic and wood.

The other benefit for jewelers is that a single machine can be used to individualize and personalize different shaped items. So, whether you’re looking to engrave rings, bracelets, necklaces or watches; it can all be done with the same machine! The only restriction is the size of your machine’s marking area. Although that is typically not a concern, as jewelry items tend to be small in size.

Versatile

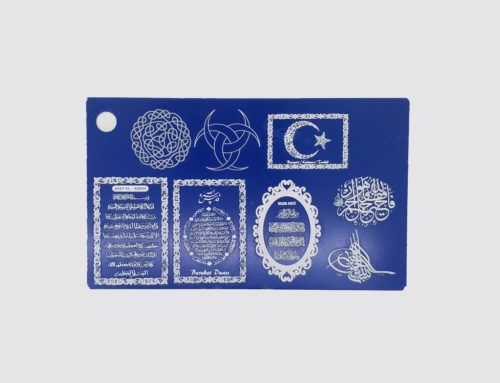

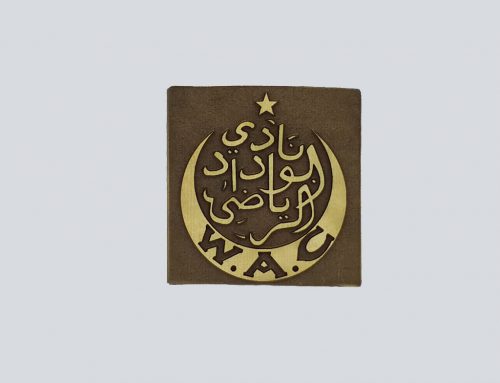

You can create virtually any design, no matter how complex, and have it successfully engraved onto your jewelry item. Even the smallest of designs remains legible when marked with a laser beam.

Thanks to its versatility, Jewelry designers use the laser machine for countless applications. Whether it’s engraving a photo onto a pendant; adding a unique pattern to a ring; branding jewelry with a logo for corporate events; or personalizing a necklace with a heart-warming message – the possibilities are endless.

Non-contact

The fiber laser machine uses a non-contact marking method. Essentially, a laser beam is directed onto the item’s surface and produces a mark by removing the material. As a result, there is no contact between the laser equipment and the jewelry item being engraved.

Since there is no contact during the engraving process, the jewelry item being marked is never compromised. Additionally, the machine doesn’t have moving parts, which can wear down over time and require replacement.

You also don’t need to trouble yourself with tightly clamping or fixing the jewelry item to an engraving bed. You just place the item in the right position and press the start button to begin the engraving process.

Time-saving

There is no doubt that one of the most significant advantages of laser engraving is the time you save! Of course, the engraving time per item varies depending on the complexity of your design and the depth of the engraving. However, it’s safe to say that the average job takes anywhere from a few seconds to a few minutes at most!

Software made easy

A major contributing factor to the rise in popularity of the fiber laser machine over the past decade is the improvements to the operating software. You don’t need to be an expert engineer to be able to use a laser machine anymore. The software is similar to other design apps, such as Adobe Photoshop and Illustrator. You can also import your existing files using common file types, including AI, DXF, Bitmap, JPG and many more.

Environmentally responsible

The laser engraving process doesn’t use harmful chemicals and is therefore considered to be an eco-friendly technology. In contrast, other manufacturing methods use chemicals that pollute the planet, such as acid etching chemicals and ink. Not to mention the burden of correctly disposing of the chemicals, which adds to the cost of production.